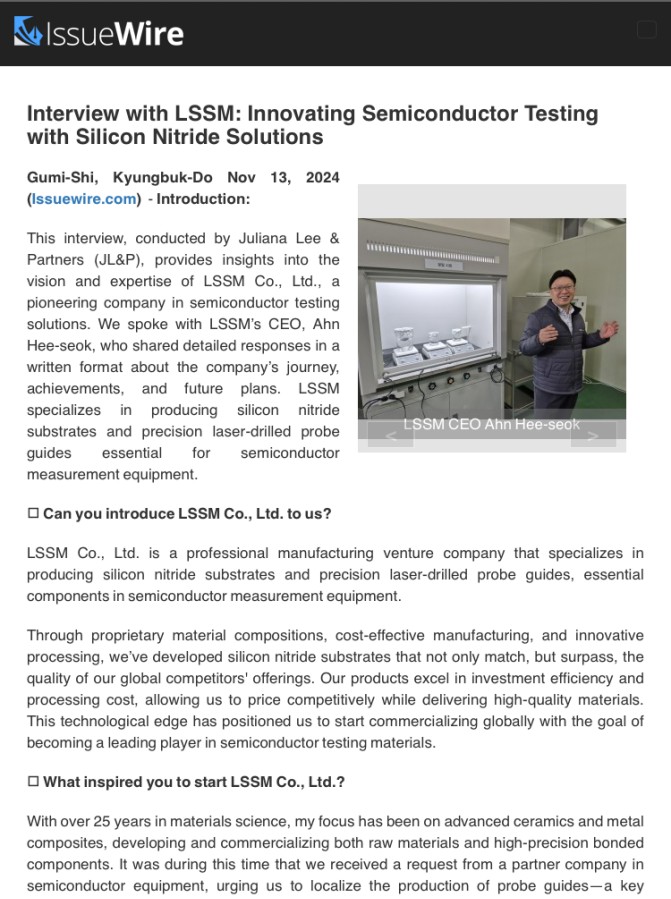

LSSM Co., Ltd.

Your Professional Silicon Nitride Probe Guide Partner, LSSM

Precision begins with us.

LSSM’s Pro-square Series

Quality and Price Competitive Silicon Nitride Probe Guide

Optimal for high spec. system semiconductor inspection equipment

Problem

Advanced High-Quality Silicon Nitride Substrate and Probe Guide Manufacturing Technology for High-Spec System Semiconductor Inspection Equipment

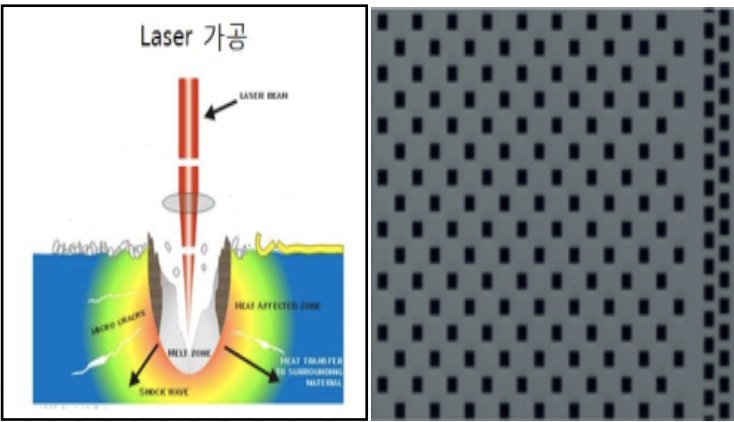

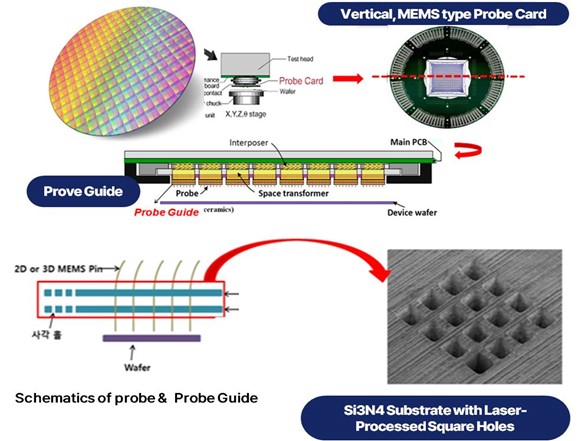

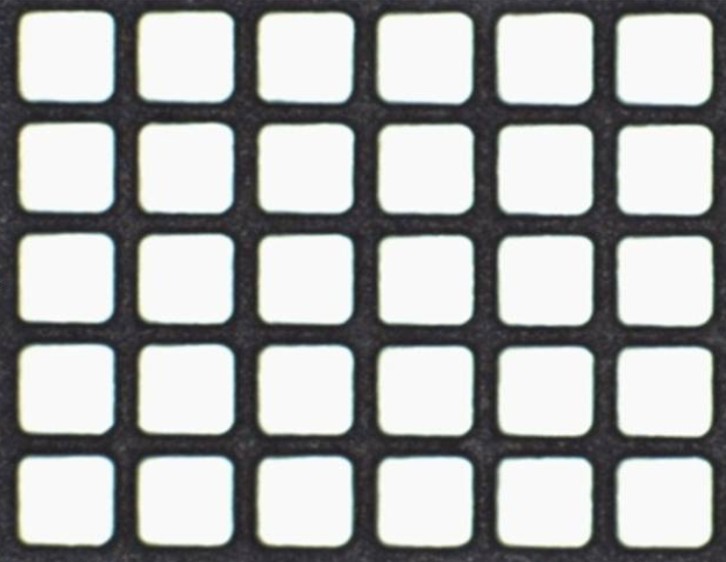

Advanced inspection equipment requires precision probe guides with ultra-fine laser-processed square holes on silicon nitride substrates. This component is essential for guiding probes with high durability and heat resistance, making it a critical and increasingly in-demand solution

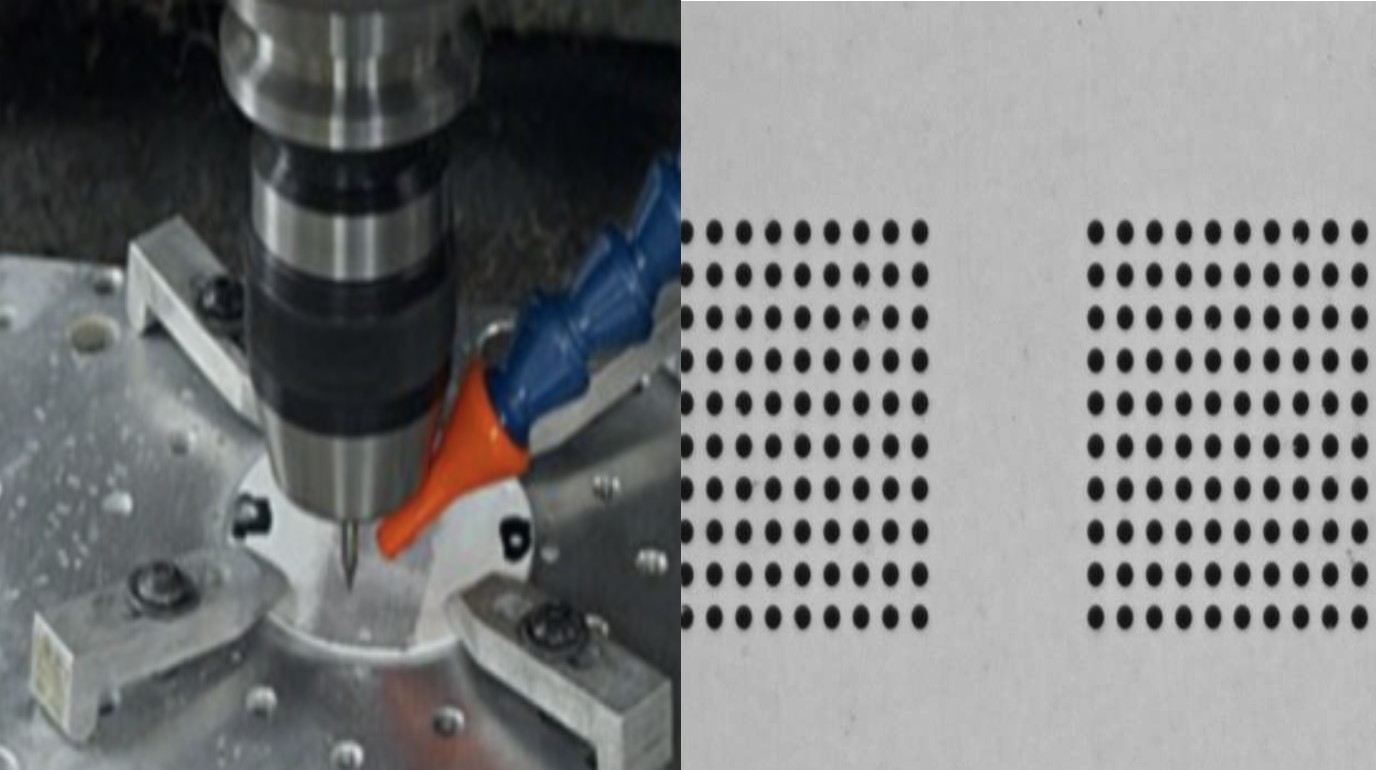

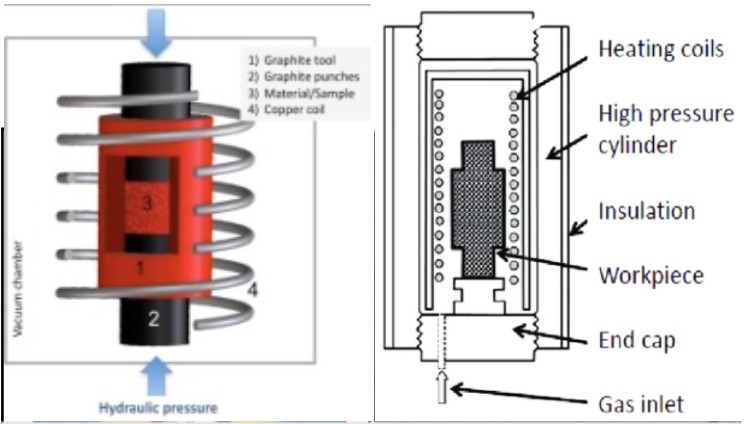

The stringent specifications and complex manufacturing process of silicon nitride substrates for semiconductor inspection equipment are currently dominated by a few foreign competitors. Their methods involve high-cost, high-temperature, and high-pressure techniques, leading to expensive products and limited supply

5G/AI

Semiconductor Demand

Rising Demand for High-Spec 5G/AI Semiconductors

Circular Probe

Equipment

Ceramic Probe Guides for Standard Semiconductor Inspection Equipment with Circular Probes

Square-Hole

Probe Demand

Increasing Demand for Square-Hole Probe Guides for High-Spec Semiconductors

Production

Costs

High-Cost, High-Temperature Silicon Nitride Production Methods by Overseas Competitors

Our Solution

(LSSM's Technical Competitiveness)

- Cost-Competitive Silicon Nitride Substrate Manufacturing Technology

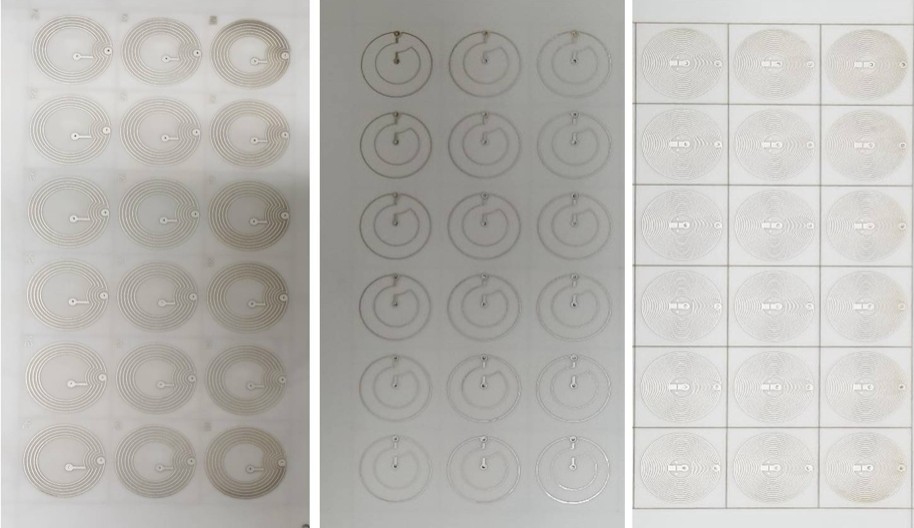

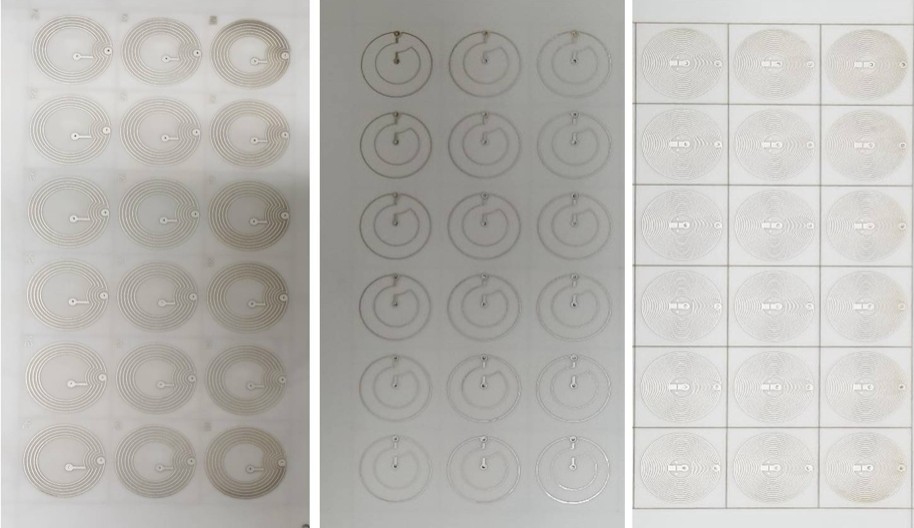

- Optimized Silicon Nitride Probe Guide Technology for Semiconductor Inspection

Proprietary material formulation for low-cost manufacturing

Low cost & Unique manufacturing equipment and process technology (Very low initial equipment investment, excellent process cost competitiveness)

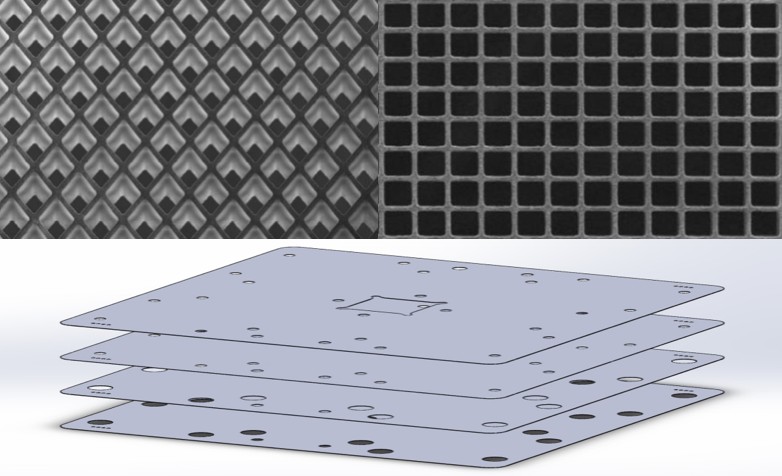

Heat Treatment Technology for Thin Plate Processing Deformation Control

Uniform density of large area compared to thin plate and densification of microstructure

World's highest specification ultra-fine laser square hole processability (square hole tolerance 1–2 μ, corner R 3–4 μ, position accuracy 2–3 μ)

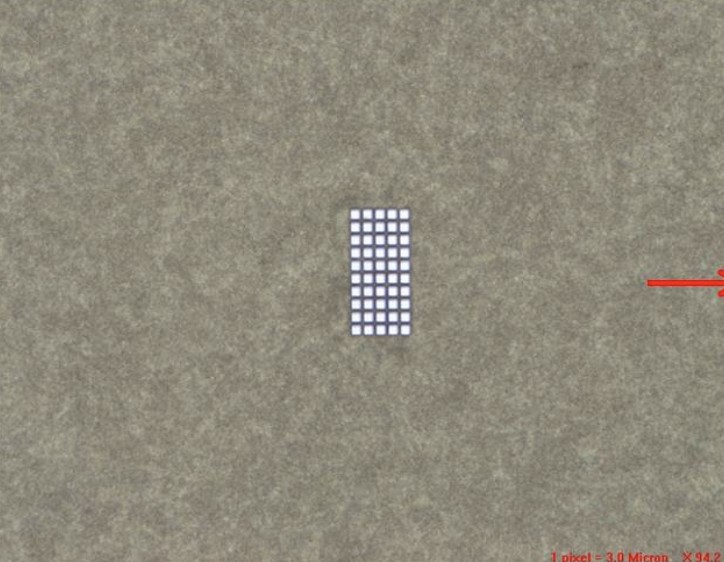

Manufacturing Technology of 2-4 Layer Bonding Probe Guide with Ultrafine Laser Square hole Processing Substrates

Products

Optimal for High-Spec System Semiconductor Inspection Equipment!

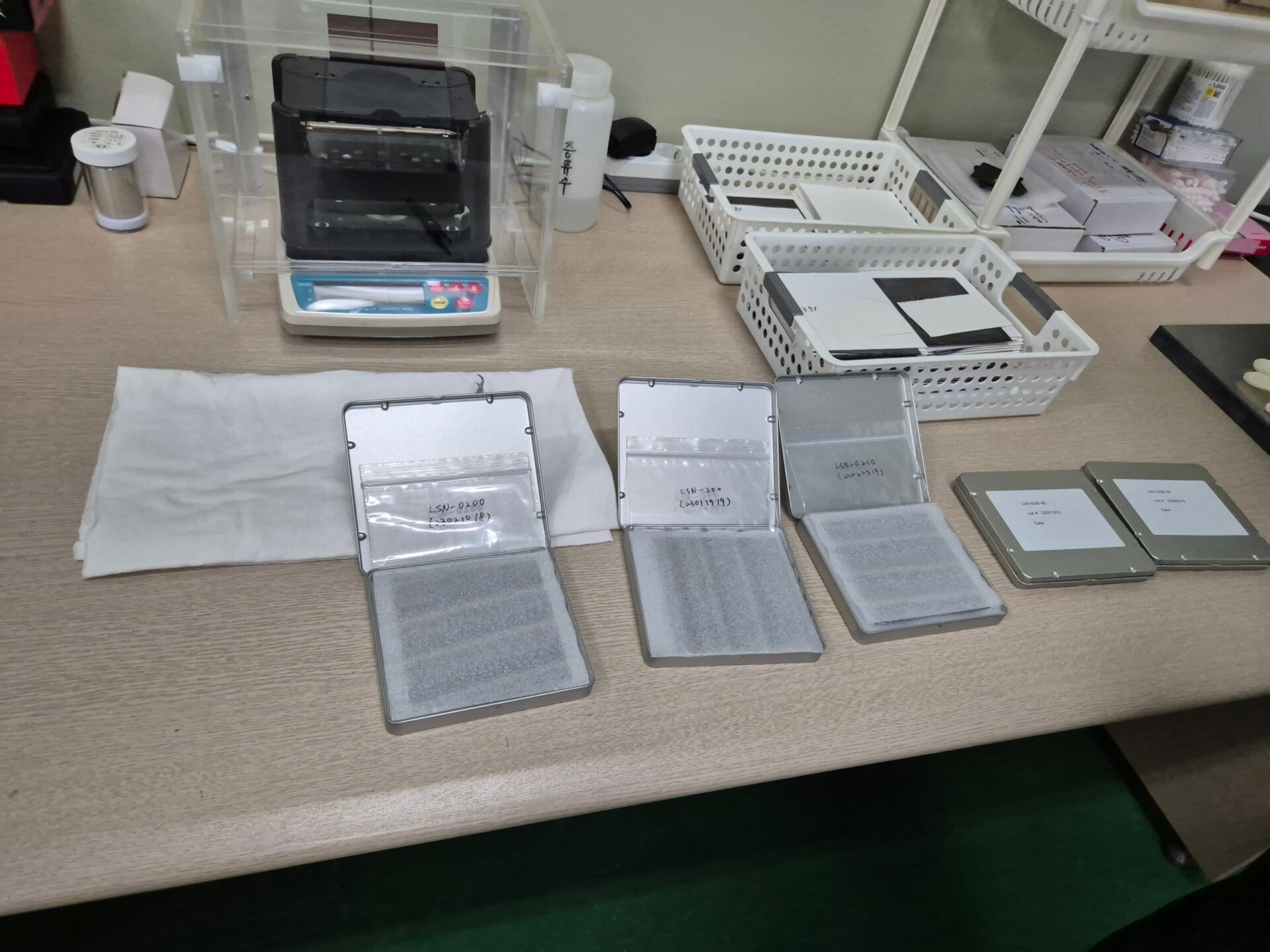

(Si3N4 Substrate : LSN-BK Series, Probe Guide : Pro-square Series)

Probe cards and Probe guides with our products for system semiconductor inspection equipment

Spec

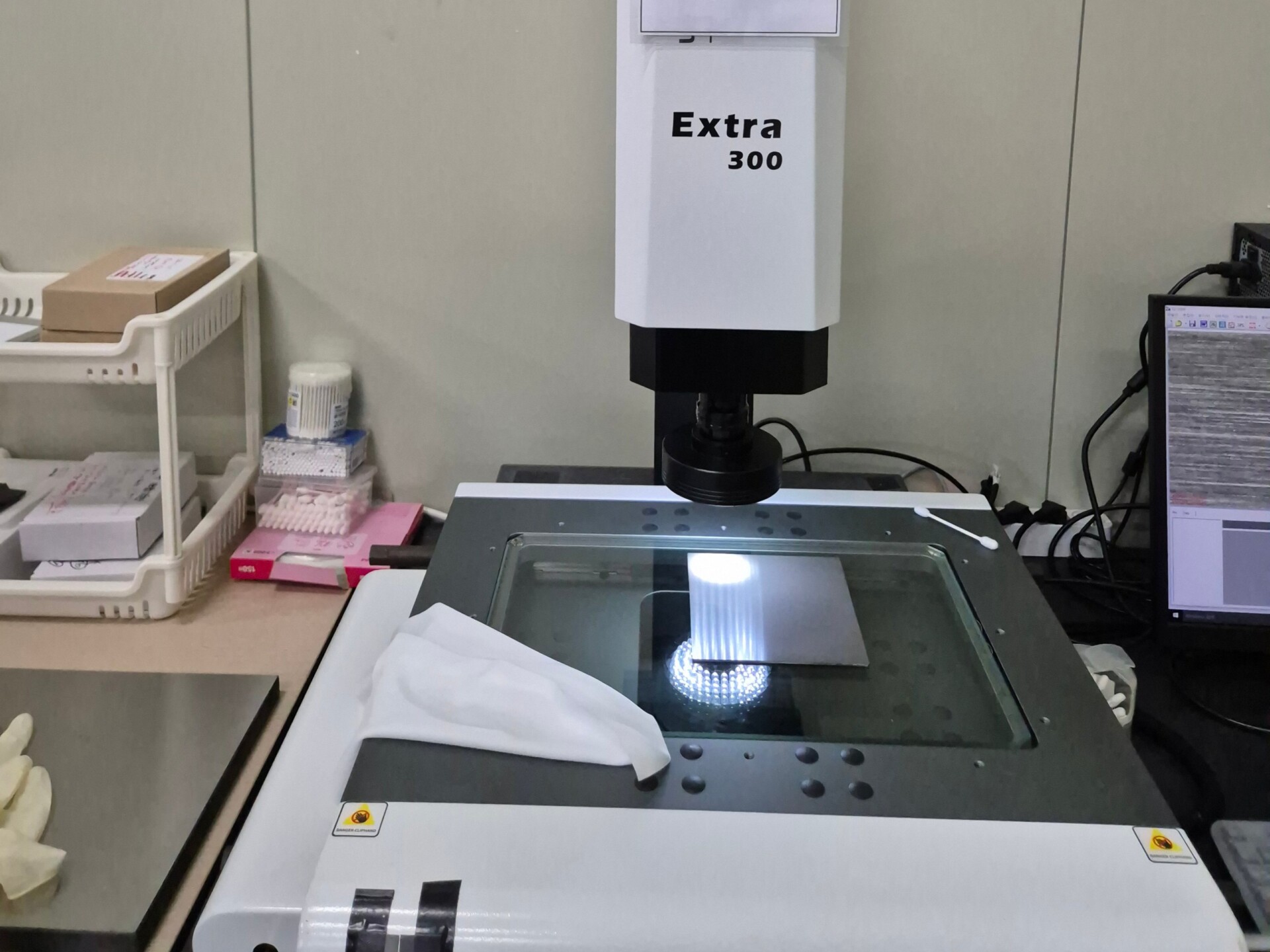

Substrate Size: 20×20 – 102×122mm, Thickness: 0.2–0.3mm, Flatness: ±0.005mm, Parallelism: ±0.02mm

Laser-Processed Square Holes: Hole size range: 30μm – 50μm, Tolerance: ±1-2 μm, Straightness: ±1-2 μm, Position Accuracy: ±2-3 μm, Square R: 3-4 μm, Layering possible up to 2-4 layers

Competitive Advantages

(LSSM Business Competitiveness)

Low-Cost, High-Quality Silicon Nitride Substrate Manufacturing Technology

Optimized Manufacturing Technology for High-Spec Probe Guides in Semiconductor Inspection Equipment

Growth Engine for Business Sustainability and Expansion

Low-Cost, High-Quality Silicon Nitride Substrate Manufacturing Technology

Very lower initial equipment investment costs compared to advanced overseas competitors

High-quality silicon nitride substrates with cost and price competitiveness

Low initial equipment investment

High-quality, Cost & Price competitiveness

Optimized Manufacturing Technology for High-Spec Probe Guides in Semiconductor Inspection Equipment

- Square hole tolerance : 1~2μ, Corner R : 3~4μ, Position accuracy : 2~3μ

- 2–4 layer bonded probe guides

- Square hole tolerance : 2μ, Corner R : 5μ, Position accuracy : 3μ

- Bonded probe guides limited to 2–3 layers

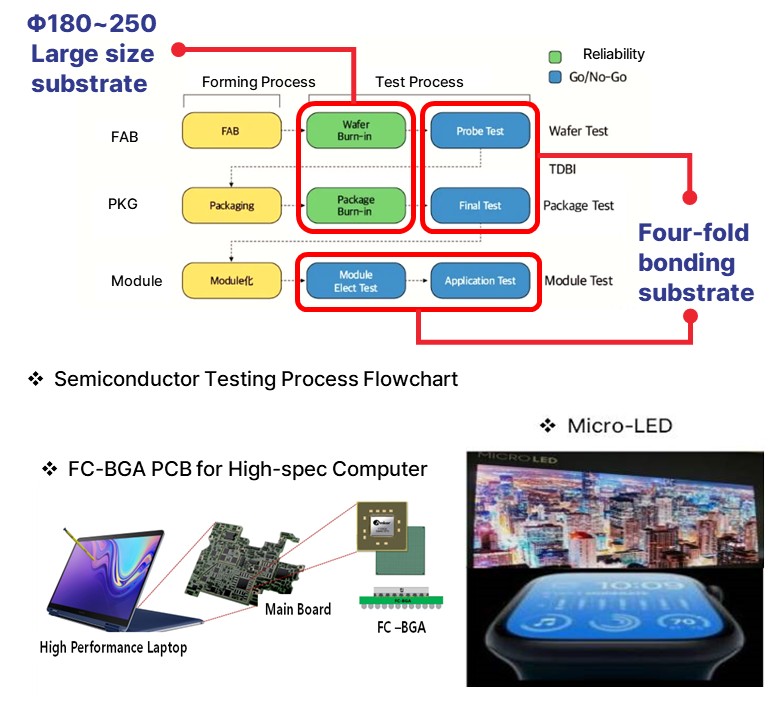

Growth Engine for Business Sustainability and Expansion

Plans for Entry into New Markets

and Applications for Silicon Nitride Materials

: FC-BGA BBT, Burn-in test,

Probe Cleaner

: Expansion in advanced semiconductor

and hydrogen fuel cell applications,

including high-spec ceramic heaters

R&D and Next-Generation Product Line

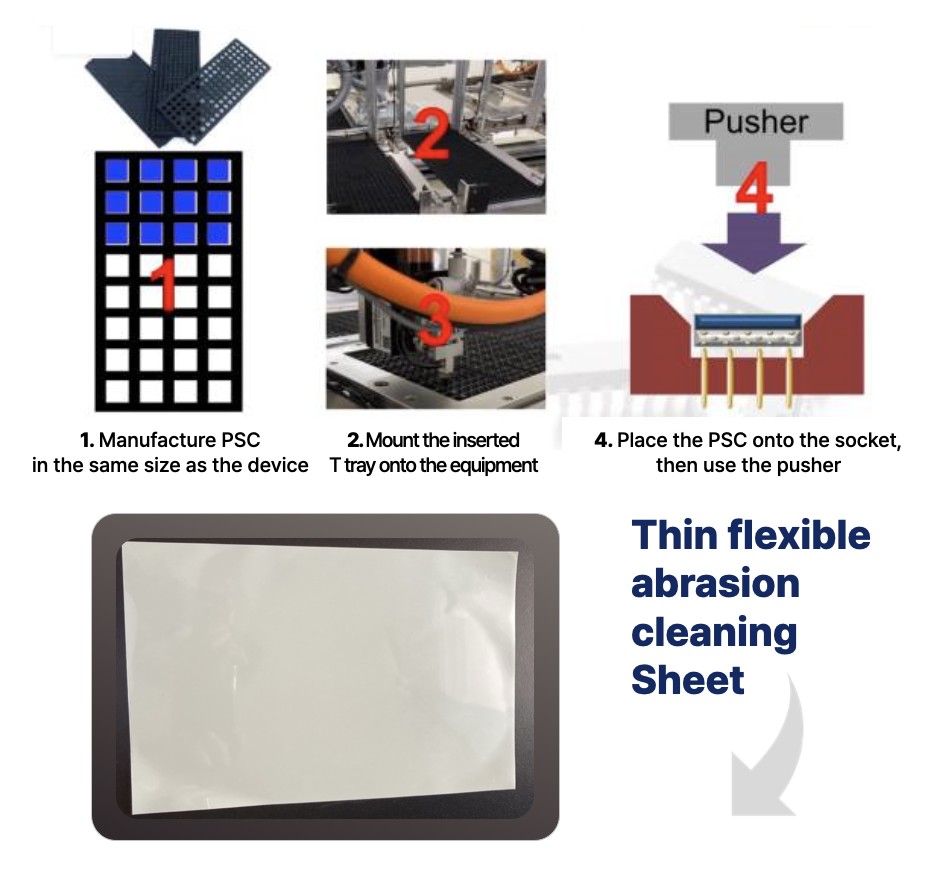

Burn in test, FC-BGA, Micro-LED inspection Probe Guide Plate

Probe Cleaning Sheet

OUR PROCESS

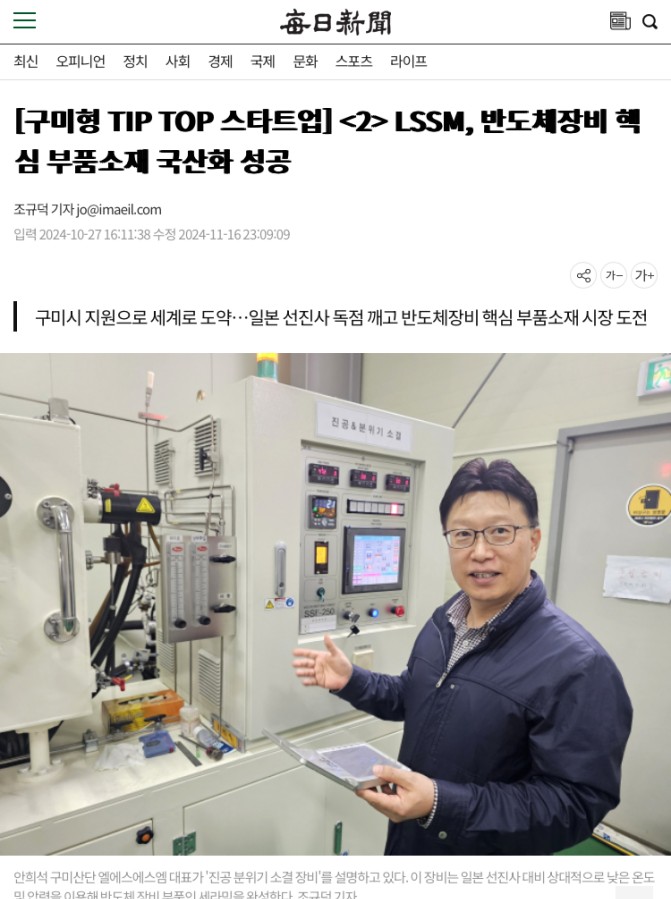

About LSSM

Our company leverages proprietary material composition and low-cost differentiated manufacturing facilities and processes to deliver high-quality products that meet or exceed those of advanced foreign competitors. By reducing equipment investment costs and enhancing raw material and price competitiveness, we have developed a robust foundation for competing in the global market.

Ahn Hee-seok

Key Personnel

Ahn Hee-seok

Jeon Myung-pyo

Marketing & Sales

Marketing Specialist

Equipment

Ball Mill

Material distribution and

enhancement of ceramic properties

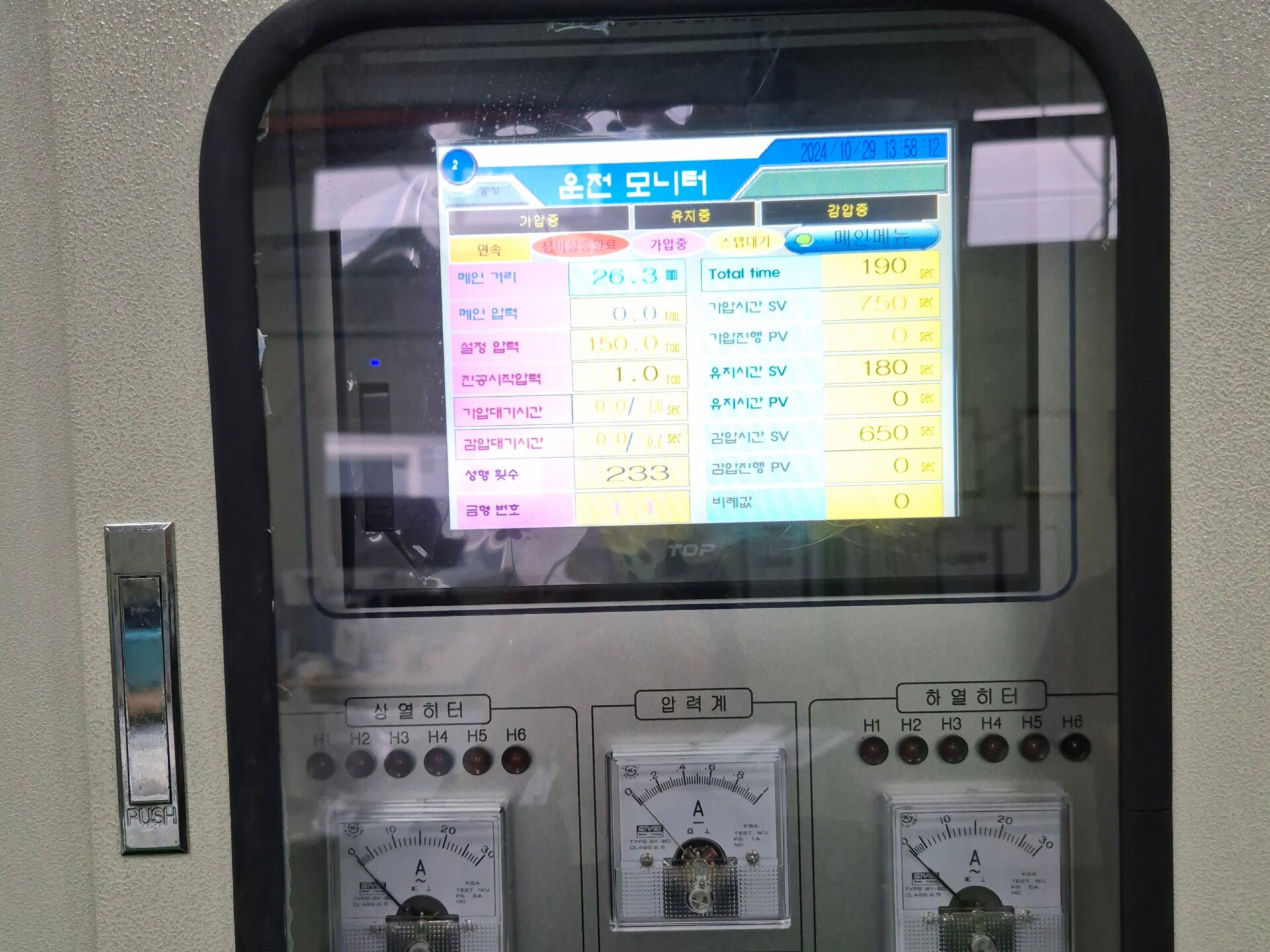

Precision Molding Equipment

Precision shaping

of materials

Atmospheric Precision Molding Equipment

Atmospheric Pressure Sintering Furnace

Vacuum Furnace for De-organic

Grinding machine

Precision Electronic Scale

Precise weight

measurement

Hydrometer

Measuring material

density in liquids

3D Vision Measuring Device

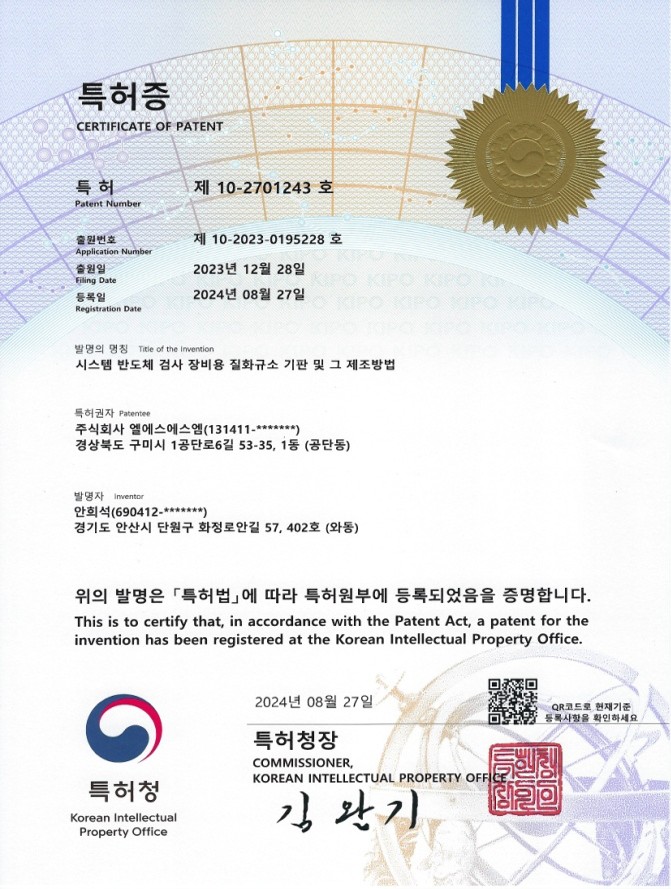

Certification

Certified Material Specialist Company

Venture Business Certification

Company History

2020

November

2021

January

2021

August

2021

December

Obtained Venture Business Certification (Certification No. 2021155030188)

2022

February

2022

September

product

market testing.

2023

December

2024

January

participated in the SEMICON

Korea Exhibition.

2024

June

international business

partnership network.

2024

October

(approx. $74,000 USD).